It's a high speed SMT production line, suitable for computer PCB, car PCB and other middle end PCB.

Yamaha Z LEX YSM20R SMT Assembly Line

Specifications:

Yamaha Z LEX YSM20R SMT Assembly Line

It's a high speed SMT production line, suitable for computer PCB, car PCB and other middle end PCB.

1. High Speed Yamaha Z LEX YSM20R pick and place machine.

Yamaha Z:LEX YSM20R, a new all-around surface mounter*1 that offers the versatility to accommodate a wide range of production formats with flexibility and efficiency while also boasting a mounting speed of 95,000 CPH,*2 making it the world's fastest in its class (under optimum conditions).*3

The YSM20, a leading Z:LEX Series model, offers high productivity, adaptability to various components and superior production changeover ability based on its “1-head solution” concept to accommodate a wide range of component sizes—from super small chips to large components—with a single type of head. The new YSM20R is a high-end, high-efficiency modular mounter that enhances the production capabilities of the YSM20 and joins the series lineup as a deluxe model aimed at boosting competitiveness.

With the YSM20R, Yamaha focused on increasing XY-axis speeds and revising the actions involved for pick-up to placement, and successfully improved mounting speed by approximately 5% compared to the YSM20. Also, by improving the performance of the wide-scan camera on the head, the YSM20R can mount components up to 12×12 mm in size (up from 8×8 mm) at high speed, thus improving productivity. Further, the new Auto Loading Feeder (ALF) using proprietary Yamaha Motor technology, the “sATS30NS” Auto Tray Sequencer (ATS) for nonstop tray replacement and nonstop feeder carriage exchange system (all available as options) reduce costs and time loss while further improving machine operation rate.

The Z:LEX YSM20R will be on display at the 47th Internepcon Japan electronics manufacturing and mounting technology exhibition to be held at the Tokyo Big Sight (Koto-ku, Tokyo) from January 17 to 19, 2018.

2. Middle Speed Yamaha YSM10 pick and place machine.

YSM10 is a new surface mounter*1 that is the world's fastest in its class*2 at 46,000CPH*3, will be available for purchase from February 1, 2017. This new addition to the line-up is a compact, high-speed model with space-saving qualities, and provides a combination of component compatibility and versatility. In addition to the high-end ultra-high-speed modular Z:TA-R YSM40R, and the upper-middle class all-round versatile high-efficiency modular Z:LEX YSM20, this new release enables the YSM series line-up to provide a range of optimum lines designed for a variety of production formats and scale sizes.

The YSM10 is newly developed based on the three "Ones" concept and provides 1) a combination of a mounting speed that is number one in its class, 2) a one-head-solution that does not require replacement, and 3) an integration of three models of the YS12 type into one platform.

While in pursuit of the ideal concept – a 1-head solution with versatility from small chips to large components, the world's fastest speed in its class, and without the need for head replacement - the new model also has a high-speed general-purpose head similar to that used in the Z:LEX YSM20, and a new generation servo system etc. creating a high-class model with the latest technology.

Simultaneously, the specifications of all three current models of the YS12 series have been integrated into one platform featuring the flexibility and mobility of the compact high-speed modular YS12; the partly simplified version of the compact economy-modular YS12P, and the highly-versatile compact modular YS12F.

In addition, pickup and recognition errors are suppressed along with reduced loss in machine stoppage due the integration of the common functionalities of the two high level machines, the Z:TA-R YSM40R and the Z:LEX YSM20 with their e-Vision for automatically creating and tracking component data, Smart Recognition for easily creating component data from complicated shapes, and Pickup MACS system for automatic correction of the component pickup position.

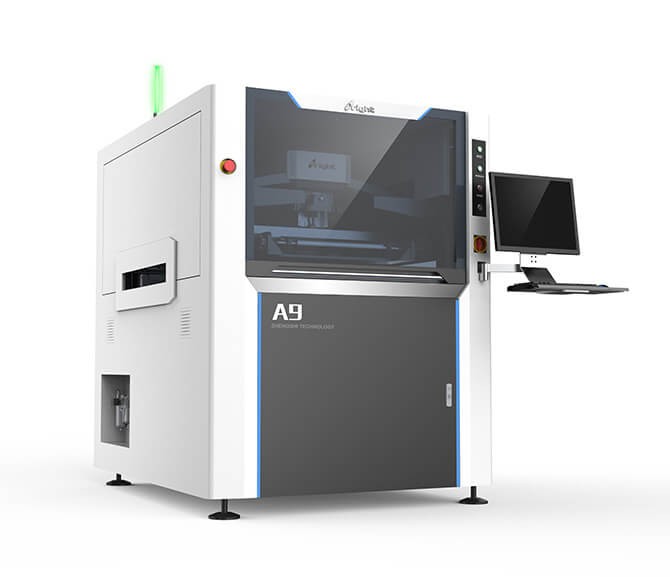

3.High Accuracy A9 smt stencil printer.

A9 solder paste printer Fully Automatic, High Accuracy smt stencil printer, which can satisfy the printing process requirements of 03015,0.25pitch high precision and high speed.

A Seriel SMT Stencil printer is high accuracy and high stability of the fully automatic printing machine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Specification :

A Series High Precision Automatic Solder Paste Printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~1200mm x 800mm;

PCB thickness: 0.4mm ~ 14mm

FPC thickness: ≦0.6mm (Excluding jig)

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,

min. ball 0.2mm;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

4. High output 6 meter 10 heating zones R10 SMT reflow oven

1. Windows XP platform, user friendly interface and easily swap between bilingual of English & Chinese.

2. Digital control system adopted with PLC and Modular circuit. Achieving high stability and repeatibility.

3. Intelligent diagnostic system (IDS) provides trouble remind, fault alert, list-out and SPC data record features.

4. Zone temperature and blower speed can be controlled Independently, to meet the high-precision requirements.

5. Effective heating zone length with uniform heat distribution.

6. Forced air cooling system with efficient cooling speed suits most kinds of lead-free soldering application.

7. PLC and PID closed loop control to achieve high precision temperature control.

8. Standard 10 couples of top and bottom zones with patented air management structure, more efficient hot air convection and faster thermal compensation.

9. The rail track is dealt with hardening process to make it more reliable.

10. Manual adjusted process track width whereas providing option of automatic by SPG gear motor.

11. Computerized controlled rail chain lubrication structure.

12. Powerful software system can save all settings and data printout capability.

13. Flux removal unit meet with environmental protection requirement.

14. Nitrogen structure is an option.

Keywords:

JUKI RS-1R Pick and Place Machine, JUKI RX-7R Pick and Place Machine, JUKI RX-8 Pick and Place Machine, JUKI RS-1R SMT Assembly Line, JUKI RX-7R SMT Assembly Line, JUKI RX-8 SMT Assembly Line.

Contact: Tommy

Phone: +86 13691605420

E-mail: sales@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China