Max. PCB width: 560 mm

13 heating zones

Weight 2800KG

Dimension 7100x1410x1500mm

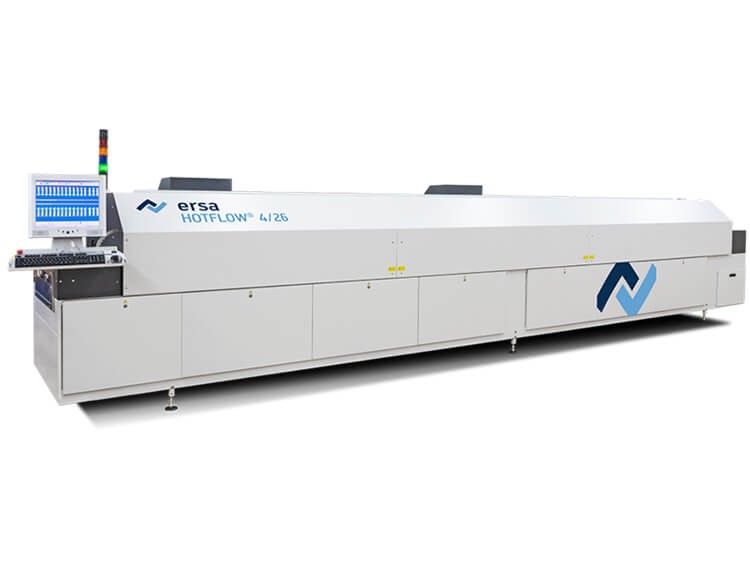

Ersa HOTFLOW 4/26 Reflow Oven

Specifications:

Excellent heat transfer with the most varied board assemblies

Rest-oxygen monitoring with low N2 consumption

Low energy consumption through intelligent energy management

Multi-level controlled cooling

Multi-level process gas cleaning system

"On the fly" maintenance for increased machine availability / uptime

Multi-track conveyor system (1-4)

Ersa Process Control (EPC) for continuous process monitoring

Ersa Auto Profiler software for quickly generating temperature profiles

Ersa HOTFLOW 4/26 Reflow Oven

The Ersa HOTFLOW 4/26 reflow system is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Through Put | 352PCB/hour |

Heating Zones | 26 zones |

Solder Peak zones | 3 zones |

Cooling zones | 4 zones |

Power | 400 V / 3 / N / PE - 50 Hz / 60 Hz |

Compressed air | Yes |

Min. PCB length | 50 mm |

Min. PCB width | 50 mm |

Max. PCB length | Not applicable mm |

Max. PCB width | 560 mm |

Weight | 2800KG |

Dimension | 7100x1410x1500mm |

Conveyor system

Working width: 45-580 mm automatically infinitely adjustable

Clear passing height: +25 (35)/-37 mm

Centre support, automatically infinitely adjustable

Conveyor speed: 20-200 cm/min

Pin-and-chain conveyor with 3, 4 or 5 mm pins

Process zone

Process length: 4,790 mm

Heated length: 3,650 mm

Cooling length: 1,840 mm

Heating system

Up to 26 convections heating cassettes

(Preheat zone up to 26 cassettes, reflow zone up to 6 cassettes)

Volumetric flow rate each module, adjustable up to 500 m3/h

Rated power each module: 3.3 kW

Cooling

Up to 4 level cooling zone with water back cooling

Electrical data

400 V, 3 Phase, N, Ground, 50/60 Hz

Continuous output during operation: appr. 9-15 kW

Exhaust

Extraction capacity 2 stacks each 400 m3/h, monitored

Keywords:

JUKI RS-1R Pick and Place Machine, JUKI RX-7R Pick and Place Machine, JUKI RX-8 Pick and Place Machine, JUKI RS-1R SMT Assembly Line, JUKI RX-7R SMT Assembly Line, JUKI RX-8 SMT Assembly Line.

Contact: Tommy

Phone: +86 13691605420

E-mail: sales@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China